Supply Chain Integration for Modern and Sustainable Warehousing

In 2023, the turbulence facing the modern logistics sector will show little sign of abating. Inflation. Covid-19. Brexit. The aftershocks of these three circumstances continue to send ripples across the sector.

Most logistics sector leaders agree that COVID-19 alone exposed workflow weaknesses that had long been present in supply chain logistics. For instance, there is the lack of upstream and downstream visibility and unexpected outages because of a reliance on manual effort logistics—something that the very first wave of lockdowns created.

In case it wasn’t apparent, the urgency for companies to optimise supply chain management and logistics quickly (SCML) has been brought sharply into focus. Many believed the solution to these challenges was next-generation SAP (systems applications and process tools), which address continual issues like inconsistent tracking and increasing transportation costs while building truly agile supply chains. But is this truly the answer?

A layered problem demands an innovative, sustainable solution

It would be great and convenient if the solution to the deluge of challenges facing the logistics sector was to scale IT infrastructures. Alas, this will not fix what some believe to be broken. January 2021 and the UK’s exit from the European Union brought new regulations, elevated costs, and additional complexities. This isn’t something that can be instantly fixed with a snap of the fingers and an IT investment.

For some in the logistics space, the ripple effect of disruption may have felt more like a tsunami. Frequent strike action, soaring inflation and the war in Ukraine and a once sturdy supply chain can be to feel a little flimsy.

Whereas there is no one solution to what some may believe to be the never-ending issues, a solution that global businesses believe to be the future is modern and sustainable warehousing.

How modern warehousing helps supply chain businesses overcome disruptions

What’s clear is that UK businesses need flexible and timely solutions to tackle the ongoing complexities facing the logistics sector, especially when it comes to warehousing.

Of course, storage capacity needs should be addressed, but so too should sustainability. One way to support the logistics sector is to promote a circular economy, where products are used, reused, resold, and recycled for as long as possible. This requires a systematic approach to how businesses perceive waste management and raw materials.

But, arguably more importantly, the circular economy analyses product sustainability and collaboration within a supply chain management framework.

By optimising supply chain logistics, production line planning, inventory management, and order distribution, businesses can reduce the time it takes to bring a product to market, something that’s imperative in today’s modern e-commerce environment.

This is what an integrated supply chain can offer businesses. But it’s more than that. An integrated supply chain can help synchronise warehouse imports and exports, further strengthening the supply chain.

The four key benefits of an integrated supply chain

The integrated supply chain (a network of suppliers, manufacturers, and distributors who coordinate with one another to complete warehousing and distribution as efficiently as possible) leverages digitisation to sync operations between all operators involved in the design, manufacture, and marketing of a product.

By integrating warehouse management systems (WMSs) within the office and warehouse, operators can easily transfer information between logistics facilities and production centres.

An integrated supply chain means process and operations information can easily be shared, no matter the status of the product in the supply chain. The four key benefits of this are:

- Elimination of escalating costs: by integrating supply chains, operators can reduce process steps, duplicate vendors, or excessive inventory, which reduces process costs. The result? The cost of storing stock can be minimised as the speed at which products move through the supply chain increases.

- Efficient logistics and production processes: by removing excess supplier leads, better coordination between operators at different stages of the supply chain is achieved, reducing errors and costs.

- Product traceability: by merging the varying communications into the supply chain, operators find it easier to trace and track stock. Having access to an overview of all communications across each stage of the supply chain, e.g., what is stored, what is in transit, what has arrived, etc., allows operators to make quick and correct decisions.

- Customer-centric vision: companies involved at all stages of the supply chain can access real-time, accurate data across all logistics and productions. By analysing historical data, organisations can make decisions to improve their levels of service delivery.

How to remain flexible and resilient

In the past, UK supply chains have been notoriously rigid and one-dimensional. For example, freight shipment routes were defined long before the journey, with little to no flexibility when in transit.

However, facilities like SEGRO East Midlands Gateway Logistics Park, a 700-acre development that has delivered over 4.5 million sq. ft. of logistics accommodation, including a 50-acre Strategic Rail Freight Interchange (SRFI), allows customers to move goods into the UK at speed, while allowing operators to make secondary decisions in real time as market circumstances dictate.

This means that bottlenecks, which could slow down shipments, resulting in products getting to market slower and potentially upsetting customers, can realistically be avoided. How? Well, businesses with a stockholding in the East Midlands Gateway warehouse can leverage its connectivity to respond to consumer demand quickly and get stock when they need it.

Then there’s the issue of supply and demand. When supply outstrips demand, overstocking becomes an issue. This issue can be mitigated by operating within a free-flowing and integrated supply chain, one with flexible warehouse solutions, where cargo spends its time in storage—something that could potentially save money on high detention and demurrage costs at ports.

Leveraging freeport zones is yet another way supply chain operators can remain flexible and resilient. To import, process, and export goods and materials without burdensome duties, taxes, and regulations, it takes much economic and logistical strain from businesses across the supply chain.

Moreover, goods and materials that arrive at UK freeports like SEGRO East Midlands Gateway Logistics Park or any other freeport can be immediately expedited without having to endure lengthy customs clearance processes. This benefits both businesses and customers because they can benefit from seamless supply chain performance.

Socially responsible business practices

A fully sustainable, integrated supply chain has one more clear benefit: the assurance of socially responsible business practises that not only benefit the earth and the 7.4 billion people who inhabit it but also business growth.

A sustainable, integrated supply chain will:

Reduce environmental impact

It is not costly for businesses to reduce their environmental impact. Quite the opposite. Businesses can reap large savings by reducing waste and increasing the efficiency of buildings, vehicles, and machinery.

For example, by changing the way it manufactured trainers and reducing its material usage by 20% and labour costs by 50%, Nike was able to gain 0.25% higher margins. This may not sound like a lot, but remember, Nike’s current profit margins are 0.0182%. *

Improved supply continuity

Operators who diversify their supply chains avoid an overreliance on a single link in the chain. If placed under stress, it could have a knock-on effect on other operators across that supply chain.

Having multiple suppliers across the UK or abroad will improve the continuity of your products and services, preventing costly downtime due to products not making it to market quickly enough.

Bolster reputation

When online information is at our fingertips. It is transparent. This is especially true of the supply chain. In effect, your supply chain affects your brand’s reputation. This affects your business’s growth.

A sustainable supply chain is one that promotes seamless fairness for everyone across the supply chain. This includes the boardroom, front office, warehouse operatives, and everyone in between.

Poor reputations can damage profits. Apple, one of the world’s biggest businesses, experienced this personally throughout the mid-2010s, when they were embroiled in scandals, including poor working conditions and the employment of underage workers in China.

Help your business to flourish

A sustainable, integrated supply chain will help businesses win more customers. Why? Sustainable credentials are important to consumers.

Businesses can further accent this by becoming internationally recognised by being awarded the ISO 14001 Environmental Management Standard. This demonstrates to existing and potential customers that your business is committed to sustainability and green solutions.

Remember, taking positive action can result in a better reputation, bigger savings, and better margins for your business.

Supply chain integration has never been more important

Successful supply chain management is one of the key drivers of a successful modern business. Processes across the whole supply chain must be synchronised. If not, the ripple effect could drastically reduce output.

Basically, if you want to minimise downtime, reduce waste, shorten product lifecycles, cut costs, and improve the customer experience, your supply chain will need to be honed, from manufacturing and warehousing to distribution.

If you don’t have an integrated, sustainable supply chain, you may be losing money. It’s that simple.

Sources: Google

Chase News

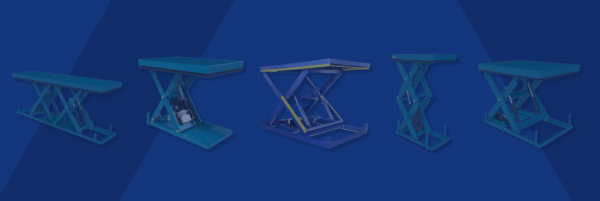

Scissor Ramps: Versatile Solutions for Efficient Material Handling

Scissor ramps, more commonly known as scissor lifts, are indispensable tools for streamlining material handling operations in various industries. They…

Read More

Loading Bay Solutions – One Stop Shop

Loading Bay Solutions – One Stop Shop At Chase Equipment, our goal is to be your one-stop shop for all…

Read More

Enhancing Efficiency with Insulated Industrial Doors

Maintaining temperature control in industrial environments is crucial for efficiency and cost savings. Insulated industrial doors offer an excellent solution,…

Read More